Advantages and Characteristics:The moving and fixed components of the Yintai linear guide MSR30E do not require an intermediate medium, but instead use rolling steel balls. Because rolling steel balls are suitable for high-speed motion, have low friction coefficients, and high sensitivity, they meet the working requirements of moving parts such as tool holders and drag plates in machine tools.

Roller heavy load type MSR30E series

The PMI Yintai MSR series roller type linear guide provides higher rigidity and load capacity on linear guides of the same size due to the use of roller rolling elements instead of general steel ball rolling elements. It is particularly suitable for equipment requirements that require high precision, high load, and high rigidity.

Overweight load

The roller type series MSR linear guide is subjected to force through the linear contact between the roller rolling element, slider, and guide rail. Compared with the point contact mode of general steel ball type linear guide, it provides lower elastic deformation under the same load and higher load capacity under the same outer diameter conditions. Its excellent characteristics of high rigidity and high load can better meet the high-precision applications of heavy load processing.

Optimization design of four-way load

Through the finite element method FEM structural stress analysis, the optimized four column roller 45 ° contact angle and high rigidity section design not only provide higher load capacity in the radial, anti radial, and transverse directions, but also can use preloading adjustment to increase its rigidity, making it more suitable for various installation methods.

MSR rail installation type

accuracy class

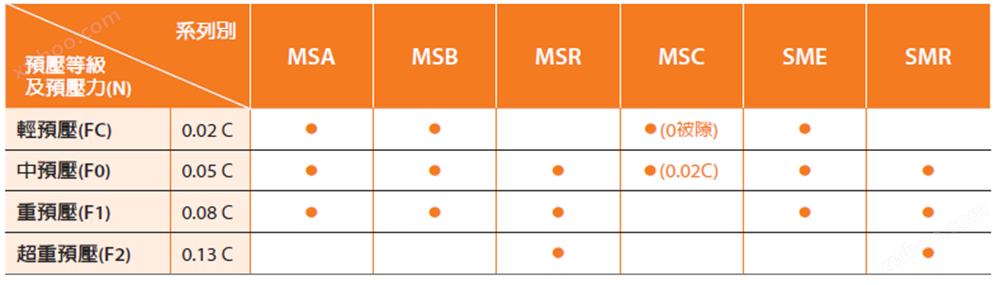

Pre compression level

Specification and model

Model and Size Table